Ruger’s Custom Shop RPR Bolt-Action Rifle in 6mm Creedmoor was made to Doug Koenig’s specifications.

Ruger Precision Rifle, the American rifle-shooting community has been keenly interested in precision rifles and precision rifle competition for several years, with each year marking an increase in both shooter participation and new products available. Appropriately, Ruger unveiled the Ruger Precision Rifle (RPR) in 2015, which pre-dates the intense interest in this field.

I wouldn’t say that Ruger created this segment, but they certainly made high-performance precision rifles financially accessible when they announced the RPR.

While the Ruger Precision Rifle has always been an excellent choice for long-range precision riflery, it needed some modification to excel in the highly specialized competitive circuit of the Precision Rifle Series (PRS). The PRS is America’s largest competitive rifle-shooting circuit with matches held around the country and competitors ranked nationally.

There’s even a finale each year that crowns the series’ top shooters. The Custom Shop Ruger Precision Rifle tested here is Ruger’s rifle that ships ready to compete in this challenging environment.

The RPR Foundation

Ruger Precision Rifle is a bolt-action, magazine-fed rifle unlike any other. The receiver is a solid chunk of 4140 steel that’s been machined to house a three-lug bolt body. The receiver sits atop a “lower” comprised of two pieces of 7075 T6 aluminum that form the trigger housing and magazine well. This is not a chassis gun that the community has become familiar with these last few years.

The advantage is there’s no need to worry about the action rattling around in the chassis when the rifle fires because the RPR has no chassis. The barrel, forend, magwell and stock all attach directly to this robust action block of 4140 steel.

A common question about Ruger’s Custom Shop rifles is whether or not the action has been “blueprinted.” The short answer is every Ruger Precision Rifle has been blueprinted since the day the rifle hit the market. Ruger does its final machining after the heat-treat process, so every Ruger Precision Rifle action consistently meets tight specifications.

This is part of the miracle of modern manufacturing, yet it is another reason we should all be thankful John T. Parsons hooked a computer up to a numerical controlled machine tool in the the late 1940s.

“Blueprinting” is nothing more than a process by which a gunsmith ensures an action matches the design drawings and was only really necessary when rifle companies manufactured for cost-savings instead of correctness. The action that made this process necessary was the Remington Model 700. Remington used to apply heat treatment after all machine processes were complete. Machining before heat treat is easier because the steel is softer and cuts better.

This approach makes the action less costly to manufacture. However, metal moves during heat treating, so action faces often were not quite square, and the tenon threads where the barrel attached had irregular contact. Hence, the rise of blueprinting actions had some utility. With the RPR, it’s completely unnecessary because Ruger manufactures these guns in the right order.

The RPR offers some flexibility with the magazines it uses to feed the rifle. It accepts both AICS-pattern and SR-25-pattern mags. The Custom Shop RPR ships with two SR-25-type Magpul PMag Gen M3 magazines, each holding 10 rounds. The PMags are true double-column magazines, so even though each holds 10 rounds, they don’t protrude far beneath the magazine well.

Additionally, every Ruger Precision Rifle features a fully adjustable folding stock. The folding mechanism requires a simple button press and then the stock folds to the left, opposite of the bolt handle. This makes transport shorter, easier and stowable for transport in the trunk of a compact car.

Comb height and length of pull have throw-levers that release tension on the comb and buttpad, allowing for quick adjustment. The stock’s toe has an M-Lok slot, so anyone desiring to attach a monopod has that option.

Custom Shop Touches

Ruger Precision Rifle touches are more significant that what’s visible in a cursory examination of the rifle. A quick visual examination shows the rifle has a gray Cerakote finish, a red anodized safety selector, a red anodized barricade stop just forward of the magazine well, and a flat-faced red anodized trigger.

About that trigger. It’s attached to an RPR-specific trigger designed and manufactured by TriggerTech (triggertech.com). To learn more about how it got in there, I called Champion Pro-Shooter Doug Koenig. Koenig is Ruger’s Team Captain and no one I know has more time shooting an Ruger Precision Rifle than he does. I’ve shot against him in a number of PRS matches and I lost every time.

Video That May Interest You

“I’ve known Mats Lipowski [an engineer at TriggeeTech] for about 25 years and I’ve used their product a lot, so I introduced TriggerTech to Ruger,” Koenig said. This trigger is a welcome addition to the Ruger Precision Rifle, not because the original trigger is bad, but because TriggerTech triggers have been getting flogged on the competition circuit for several years and are Combining accuracy and durability, the stainless-steel, hammer-forged barrel is chambered in 6mm Creedmoor.

one of the best and most durable options out there. Ruger puts a “Special” model in the Ruger Precision Rifle, complete with a vertical sear. Pull weight is adjustable between 1 and 3 1/2 pounds.

The barrel that Ruger puts on the Custom Shop Ruger Precision Rifle is also a big deal. The regular RPR comes with chromoly steel hammer- forged barrel.

This Custom Shop Ruger Precision Riflebarrel is made from stain- less steel and has a heavier contour than the base-model RPR. In what is a most uncommon combination, the Custom Shop RPR’s barrel is both stainless and hammer-forged, bringing us the advantages of both.

Stainless steel sees a lot of use on precision rifle barrels because of the consistency it offers from a manufacturing standpoint. Stainless steel machines easily while still being hard and corrosion-resistant. Unusual for a stainless-steel barrel, Ruger also hammer-forges them. Hammer-forging work-hardens the bore, which makes it more durable, while offering consistent grooves because the steel is hammered around a mandrel.

I asked Koenig about how long his barrels were lasting and he replied, “Longer than I expected, and longer than what others are experiencing.” Most competitive shooters will pull a 6mm Creedmoor barrel at around 1,400 rounds because speed starts to drop, and accuracy soon follows.

Recommended

New for 2023: Christensen Arms Modern Hunting Rifle (MHR)Read Article

Hot From SHOT: 10 Great Rifles and Shotguns for 2023Read Article

The Must-Have Gun: Getting Ahold of the M1 CarbineRead Article

New Colt CBX Precision Bolt-Action Rifle in 6.5 Creedmoor and .308 Win: First LookRead Article

“I’ve got between 1,700 and 1,800 rounds on two rifles, and only pulled one barrel because I don’t want to take it to a match this weekend in case it starts losing velocity,” Koenig added. “I’m going to put it back on my rifle after the match because I want to see how long it will last.”

Doug is seeing longer barrel life because of the hammer-forging process. The load Koenig shoots is almost exclusively one he developed for his rifles. It consists of a Hornady 110-grain A-Tip and 41.1 grains of H4350. Velocity is just a hair more than 3,000 feet per second (fps).

Hammer-forged barrels are known for durability — not accuracy. Koenig told me about his local range and how they hang golf balls at each 100-yard target out to 900 yards.

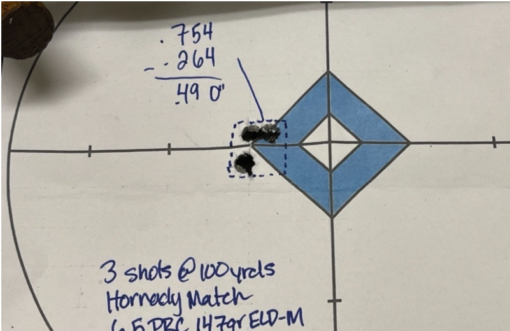

“I hit the 900-yard golf ball twice in five rounds,” he said, “and the group measured 21/2 inches high and 11/4 inches wide.” (He even sent me the pictures to prove it — and that’s with factory barrels using his handloads!)

When asked if there was anything unique that Ruger did to these barrels, besides the heavier contour and stainless steel, Koenig noted, “They do a honing process on the Custom Shop guns.” While regular RPRs have a reputation for accuracy, the new Ruger Custom Shop Ruger Precision Rifle shoots even better.

The handguard surrounding the barrel is also unique to the Custom Shop RPR. It has M-Lok slots along both sides and the bottom, but it also has an Arca-Swiss rail machined along the underside.

The Arca rail allows the shooter to quickly attach and re-position bipods, tripods, or bag. These help stabilize the rifle when shooting on barricades. The Arca rail is a wonderful addition to any rifle that needs to be fast and accurate from field shooting positions.

The final Custom Shop touch that I love is the massage that the fire control system received. This Ruger Precision Rifle has the latest firing pin, plus some internal polishing that yields a light and smooth bolt lift. The bolt body also has a nitride coating that helps smooth the lift even more through 70 degrees of movement.

These Custom Shop refinements add up to a rifle that is accurate, reliable, and ready for competition. Even if com- petition isn‘t your thing, it’s still a rifle that’s finely tuned for precise long-range and positional shooting.

Reviews

There are no reviews yet.